| Industrial output | ≤1500kg/hr |

| Belt width | 650mm |

| Dough width | ≤600mm |

| Dough thickness | 3mm-30mm |

| Butter tier No. | ≤7 layers |

| Butter:dough | 1:1-1:10 |

| Power | 15kw |

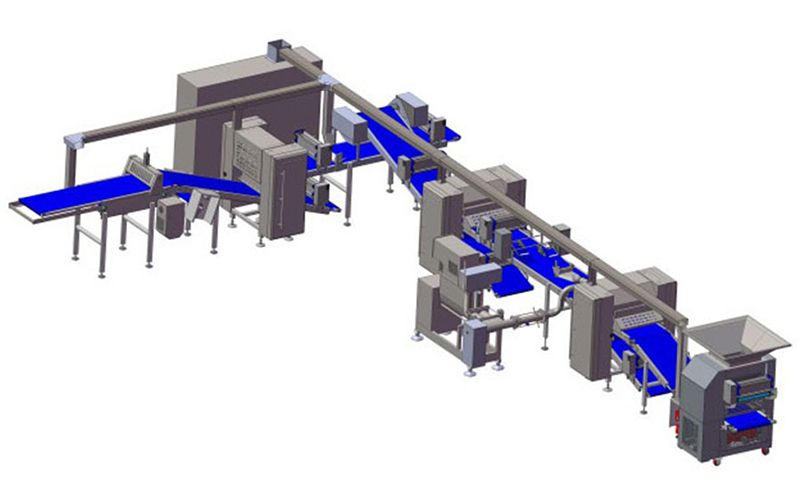

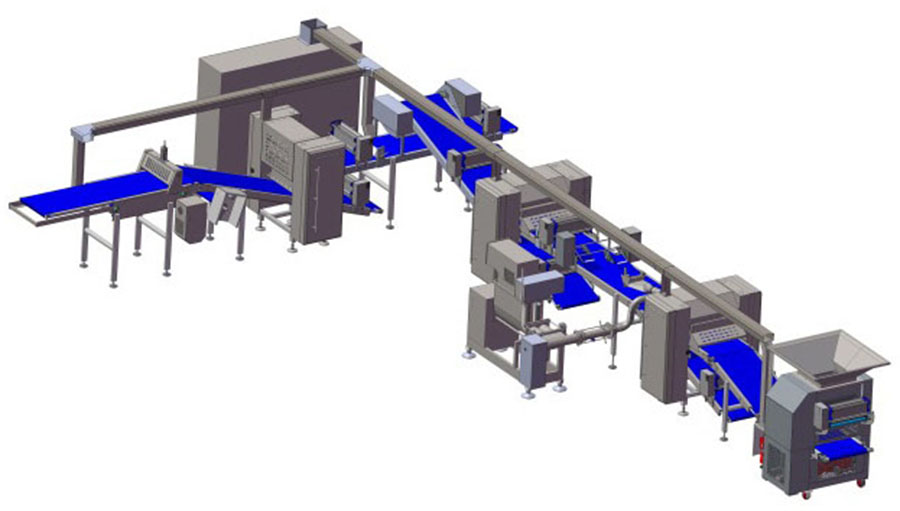

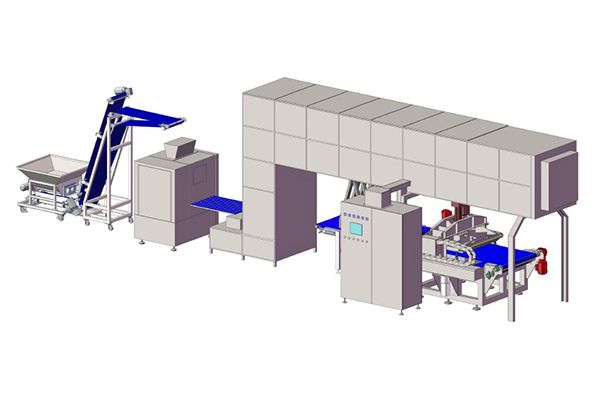

| Line type | L shape |

| Line size | L 13.0m* W8.5m* H2.4m |

| Hopper height | 2100mm |

| Hopper volume | ≤ 200kg/time |

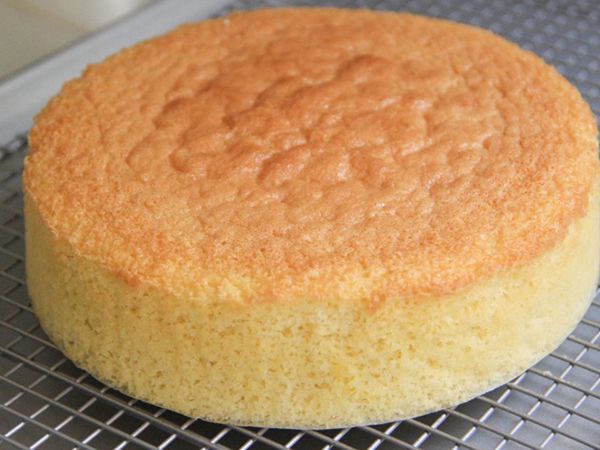

- Product quality is stable and pretty.

- The proportion of dough and butter can be adjusted according to specific demand;

- Equipped with Video monitoring equipment, easy to watch the running situation of main part to reduce the downtime.

- Abnormal data can be found and optimized by the remote control system.

- Thickness can be adjusted automatically. One-click switching of multiple products’ production can be achieved by saving formula.

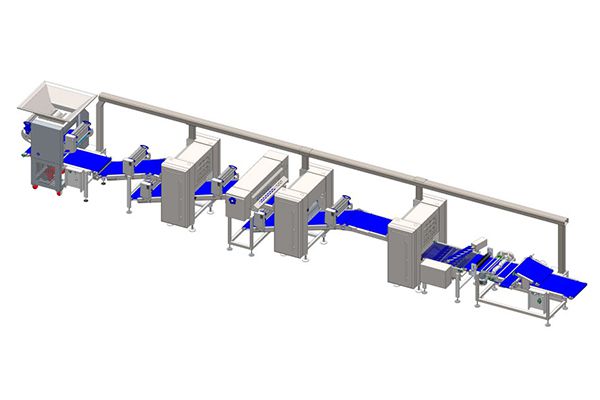

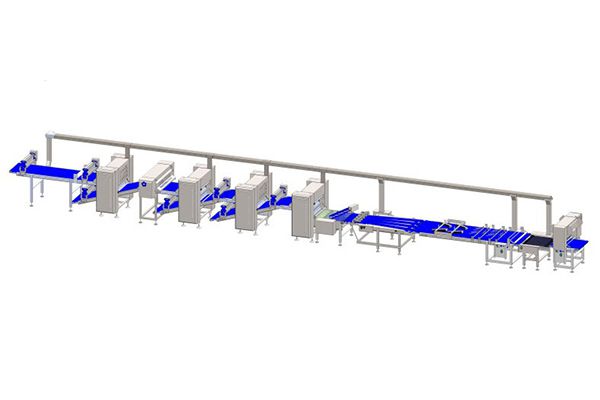

- Hopper & extruder

To divide the mixed dough into pieces, and extrude the pieces into continuous dough band. Coming out dough band with 600mm; thickness 1.5~2.5 cm adjustable; With wheels, easy to remove when cleaning and maintenance - Calibrator

To reshape the dough band with ideal width and thickness and enable the dough with pretty texture. - Satellite/ Multi-roller

To further press the dough with needed width and thickness. With 12 smaller solid rollers above and 1 big roller underneath; Each smaller roller can be detached for cleaning. And the dough band thickness before and after satellite is Max. 10:1, and adjustable; - Fat pump

To squeeze the butter/ margarine / shortening out and folded into dough band with folding unit. - Laminator

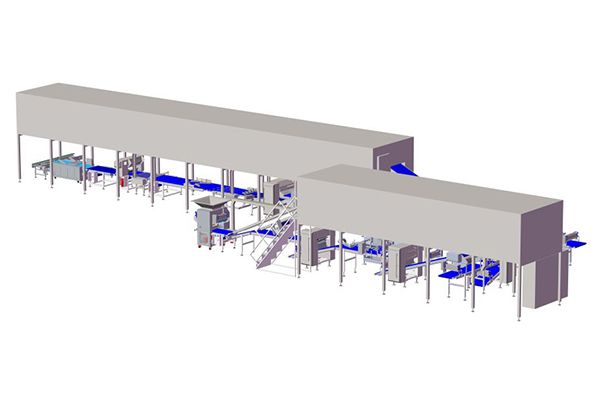

To fold the dough band to get the layers. - Equipped with Freezer to produce frozen pastry dough

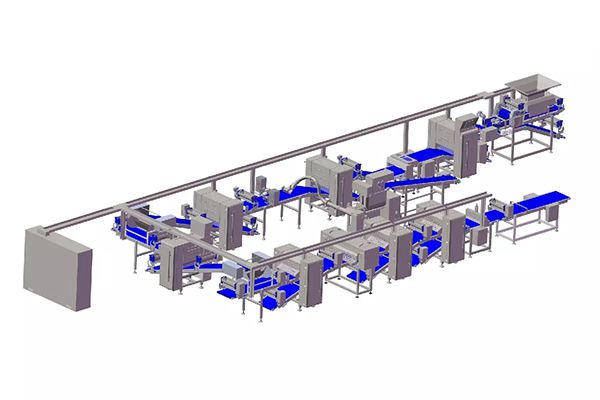

Max. capacity up to 2500kg/h of dough. Flexible modular design. Freezing temperature -40℃