Contact us today and tell us about your requirements, let's find a solution to your production needs.

-

-

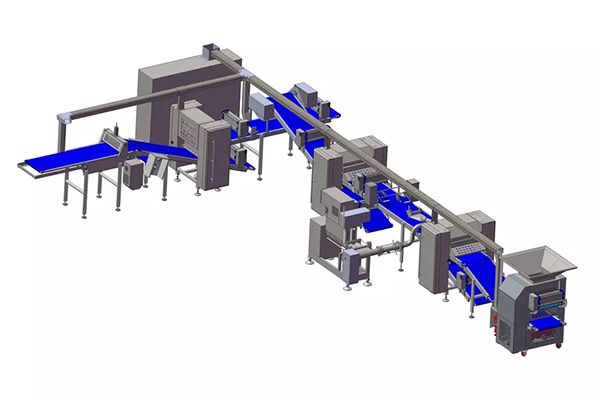

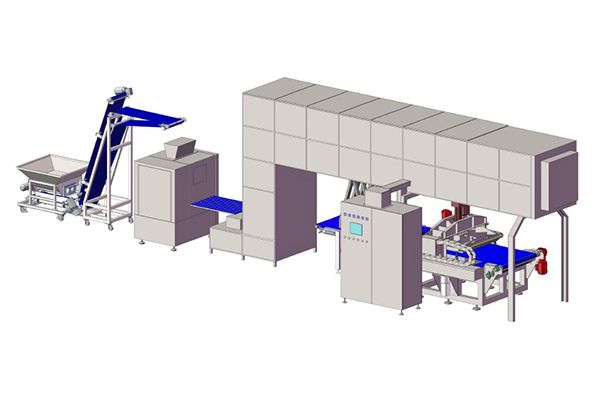

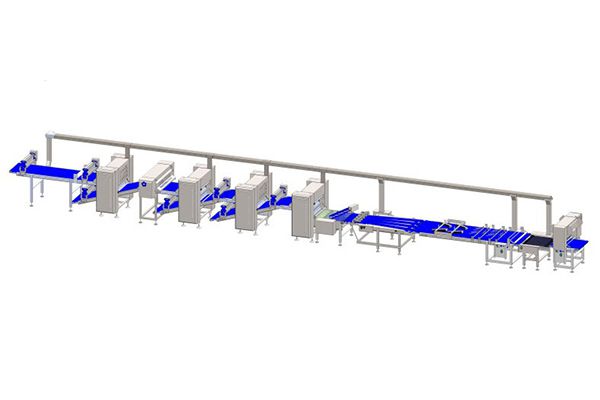

Pastry Dough Laminating Line Compact dough laminating line delivers automated, cost‑effective lamination for puff, croissant and Danish pastries. Space-saving, stainless‑steel design offers high output and consistent quality. Discover our line

-

-

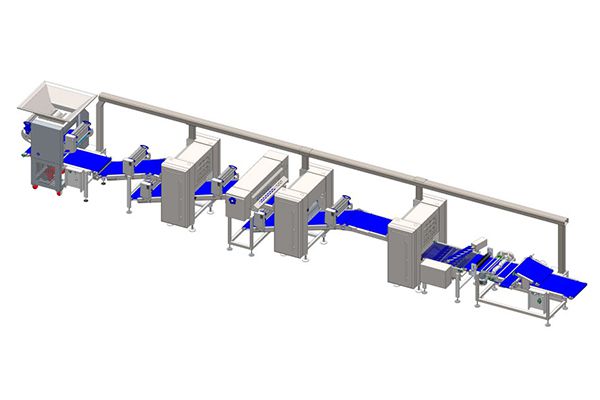

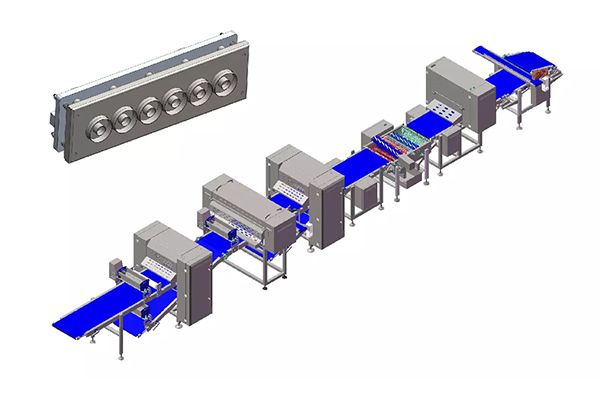

Pastry Make-Up Line Descover pastry make-up lines ZLINE offers for pastry and croissant production. Engineered for exceptional croissant and pastry production, our make-up lines combine space-efficient design, intuitive operation, and rock-solid reliability to maximize your bakery's efficiency. Discover our line

-

-

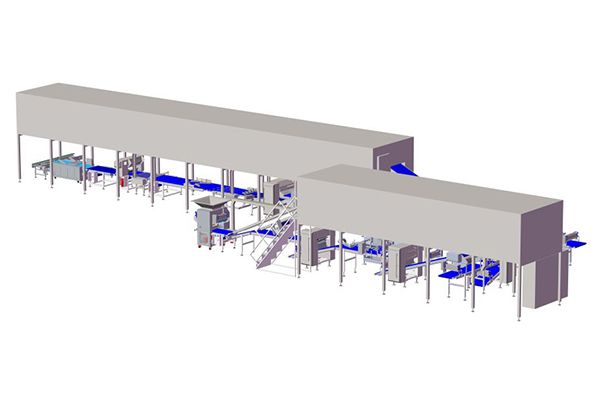

Flatbread Sheeting Line Discover our Flatbread Sheeting Line for pita, paratha/roti canai, tortilla, and more. Semi-/fully‑automatic, flexible sizing, high throughput, stress‑free dough handling—ideal for industrial flatbread production. Discover our line

-

-

Pizza Line Our complete pizza production line and automatic pizza line are ideal for high-volume pizza production with customizable configurations for various pizza sizes and styles. Discover our line

-

-

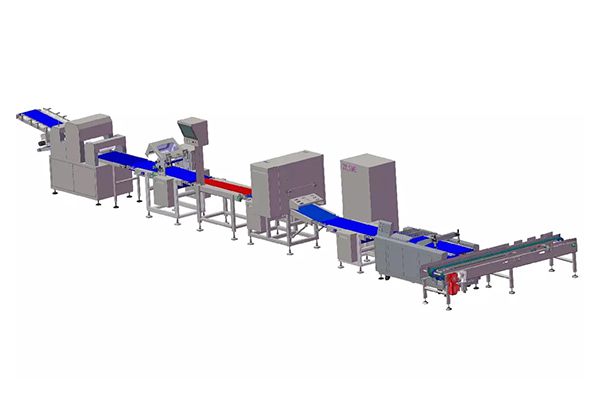

Bread Line Explore our bread production line equipment designed for bakeries. With high capacity and user-friendly features, our machines enhance efficiency and boost your productivity. Discover our line

-

-

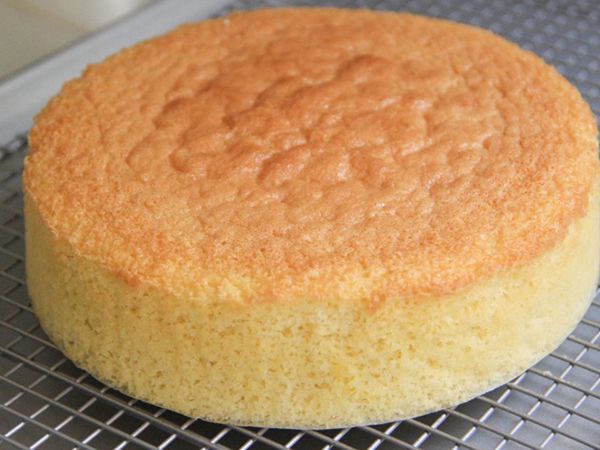

Cake Batter Aeration Machine Discover our batter mixing systems for sponge and chiffon cakes. Includes compact and full-size models designed for consistency, easy operation, and scalable bakery production. Discover our line

-

-

Donut/Berliner Line This bakery line is ideal for the automatic production of donuts and berliners. After dough mixing and fermentation, the prepared dough is placed on the infeed conveyor. It then passes through a sheeter, forming a continuous dough sheet. Discover our line

-

-

Small Bread Line This bread production line is designed for making a variety of breads and pastries. Whether you want to produce round, rectangular, oblong, or square shapes, it can all be done on a single bread line. Discover our line

-

-

Food Processing Machines ZLINE is a manufacturer of bakery equipment, discover our food processing machines ideal for automatically shaping and forming various bakery products. Discover our line

As a specialist in bakery equipment manufacturing, ZLINE delivers complete turnkey solutions, from planning and design to manufacturing and installation. Combining expert engineering, precision manufacturing, and intelligent automation, we optimize your entire production workflow. Our tailored solutions support a wide range of bakery products, including:

- Hamburger buns

- Pizza and pastries

- Custom traditional pastries

- Customized design: Develop tailored solutions for each bakery machine based on your products characteristics and capacity requirements.

- Precision manufacturing: All our bakery equipment is made with food-grade stainless steel and undergoes advanced anti-corrosion treatment to ensure long-term durability.

- Smart integration: Automate processes of dough mixing and sheeting, improving its consistency and quality.

- Factory testing: Every machine undergoes rigorous performance testing before delivery.

- Installation and commissioning: Provide on-site installation and hands-on operators trainings for seamless operation.

- Technical support: Long-term assistance with remote diagnostics and on-site service for uninterrupted production.

As a specialist in bakery equipment manufacturing, ZLINE delivers complete turnkey solutions, from planning and design to manufacturing and installation. Combining expert engineering, precision manufacturing, and intelligent automation, we optimize your entire production workflow. Our tailored solutions support a wide range of bakery products, including:

- 200+ Custom Solutions Delivered: Deep expertise in bakery processes and client-specific needs.

- Energy-efficient Machinery Design: Integrate intelligent systems, reducing electricity costs by 20-30% while maintaining high product quality.

- Hassle-Free Project Execution: A dedicated project manager ensures timely delivery and reliable performance at every stage.

Owing to keeping an eye on the development of market and customers’ requirements, ZLINE develops various powerful lines for producing frozen laminated dough, Danish pastry, puff pastry, croissants, flat breads (Tortilla, Roti, Chapatti, Pizza, Pita, etc.), breads and cakes, ect. While ZLINE’s subsidiary SOLO is able to provide clients with compact flexible lines and modular machine unit for making breads, pastries, moon cakes, cookies, Lacha paratha, and Chinese pastries, ect. Mature equipment technology makes ZLINE realize the well combination of dough and machinery, which can turn client’s new products into a reality.