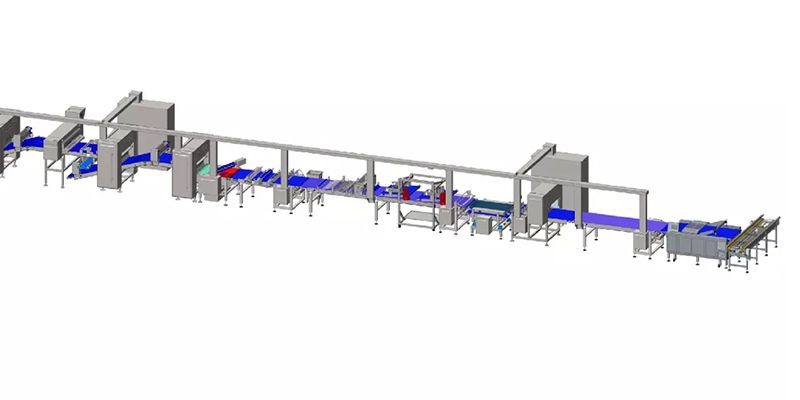

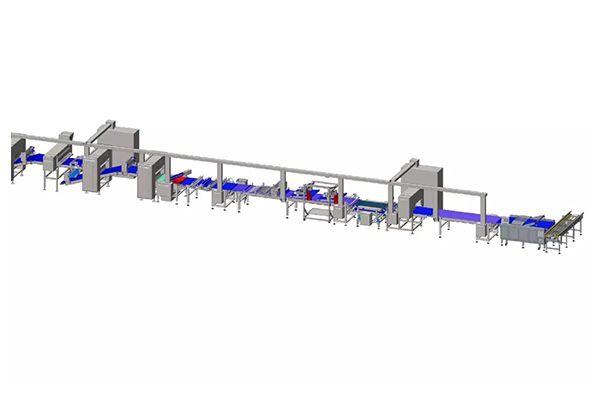

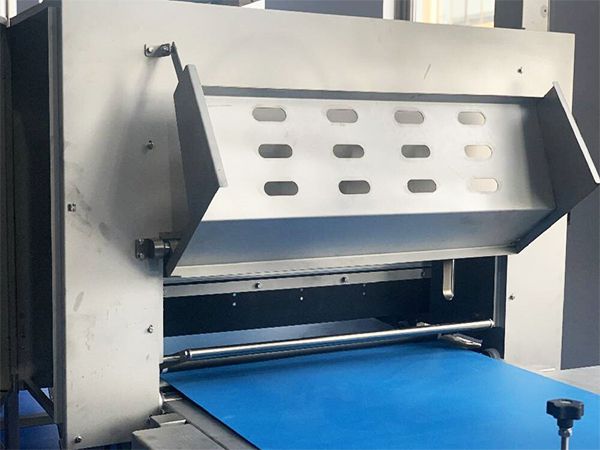

| Line model | ZKS650 |

| Line type | Straight line |

| Belt width | 650 mm |

| Dough width | 600 mm |

| Industrial output | no more than 1000 kg/hr |

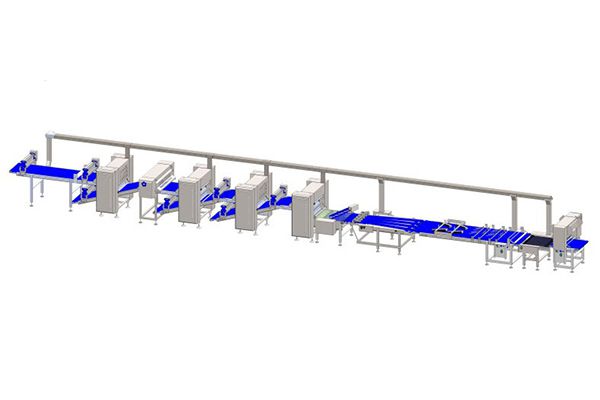

| Product size | can be customized |

| Product shape | can be customized |

| Voltage | 380 V,50 HZ,3 PH (can be supplied based on production area) |

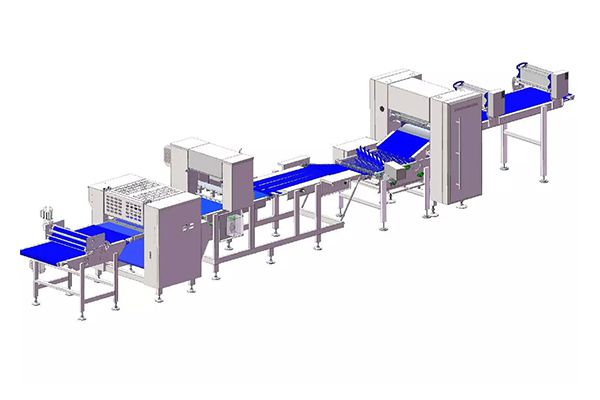

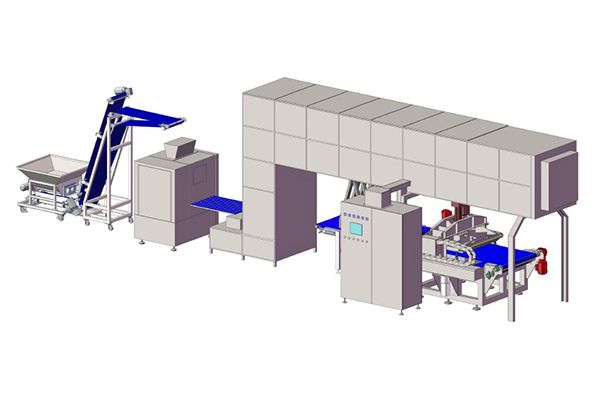

- Fully automated operation via user-friendly touchscreen for precise control.

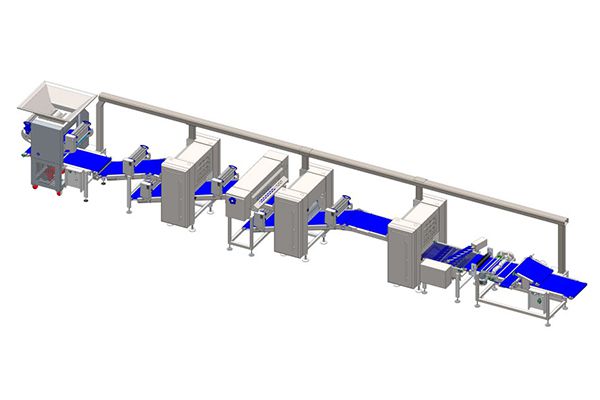

- Quick-install interchangeable forming tools for diverse products (e.g., croissants, Danish, rolls).

- Compact design requires minimal space and a low investment budget.

- Food-grade 304 stainless steel construction for long-term reliability.

- Equipped with a remote control for quick monitoring and troubleshooting of minor issues.

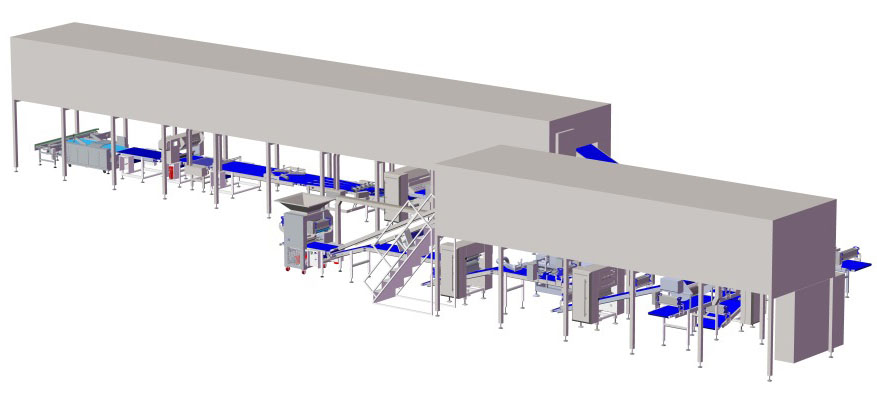

Various pastry decorating tools can be customized according to customer requirements. These include rotary cutters, straight cutting blades, braiding, intermittent cutters, perforation units, and lattice cutters.

The spacing between the tools and the shapes can also be customized – even small holes can be made in the exact size you need.

A wide range of forming tools can be tailored to match your pastry production needs. For example, a folding unit wraps filled dough, while a rolling unit shapes filled dough into long cylindrical rolls for easier cutting. Cutting blades can also be custom-made to match the shape of your bakery product, including straight blades, triangular blades, toothed or non-toothed D-shaped cutters, and other special shapes.

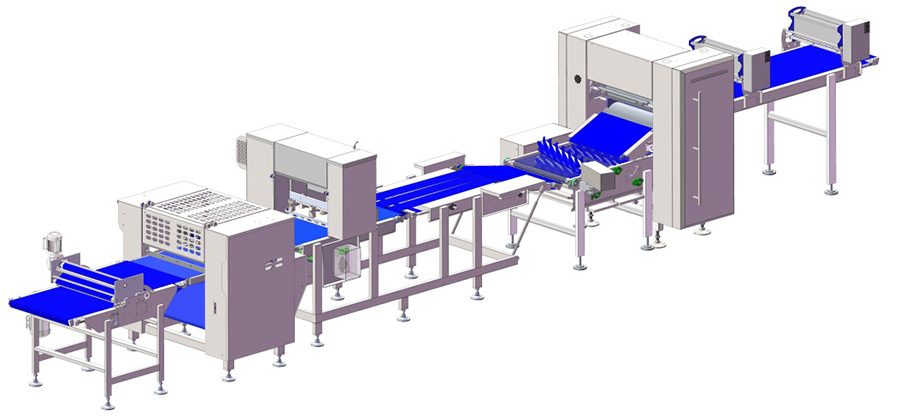

User-Friendly Design Features:

- Quick-change tooling system for fast mold installation/removal

- Material options: 304 stainless steel or PTFE-coated carbon steel

- 100% food-contact surfaces made of antibacterial, food-grade materials