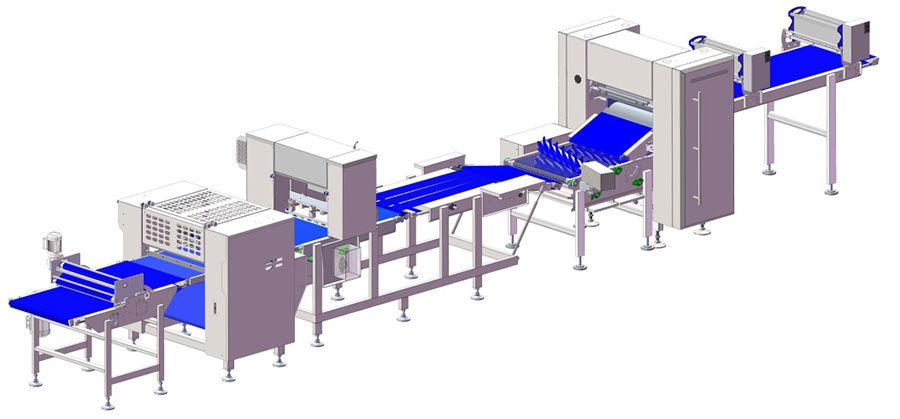

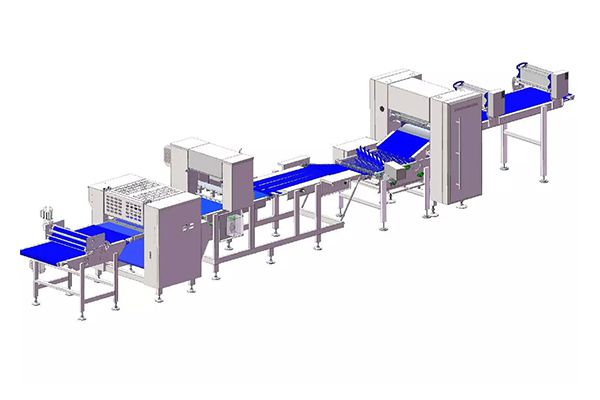

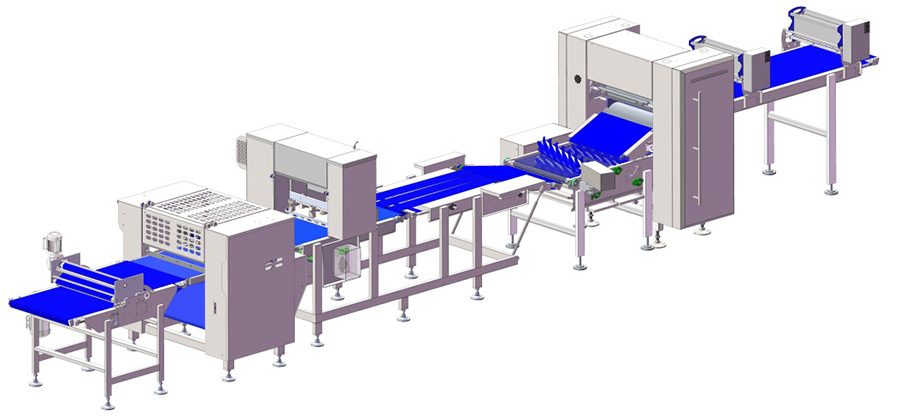

| Industrial output | 15-25g: 9000p/hr 30-75g: 5400p/hr |

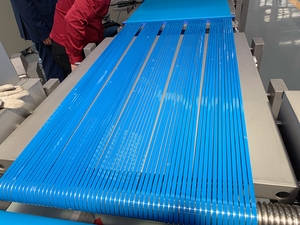

| Belt width | 650mm |

| Dough width | ≤600mm |

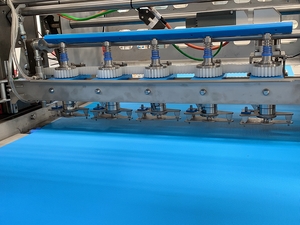

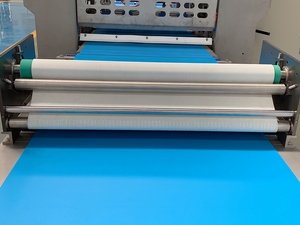

| Dough thickness | 3mm-8mm |

| Power | 15kw |

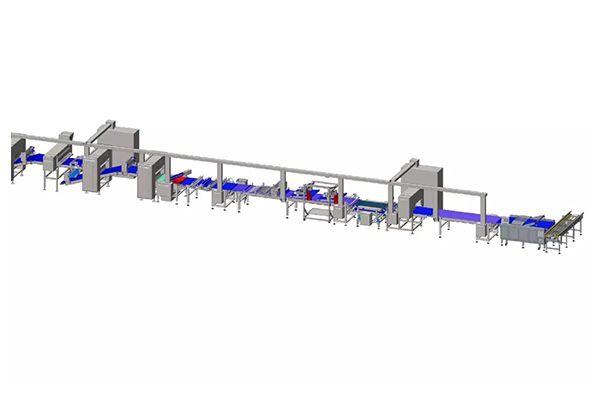

| Line type | Straight |

| Line size | L 11m* W 1.8m* H 2.2m |

| Machine weight | 9000kg |

- Different sizes and shape are accessible on the same line.

- Abnormal data can be found and optimized by the remote control system.

- Thickness can be adjusted automatically.

- Main materials is 304 stainless steel and PU belt in food grade. Durable structure.

- Capital budget and space needed are less.

- Compared to hand-made or made by small machine units, this line can produce high quality croissants in a higher automation.

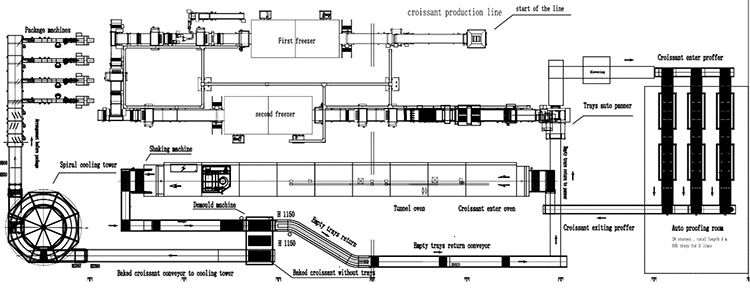

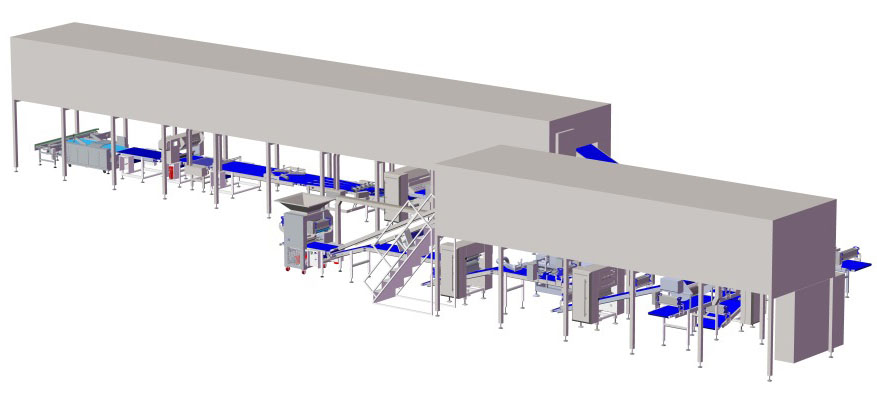

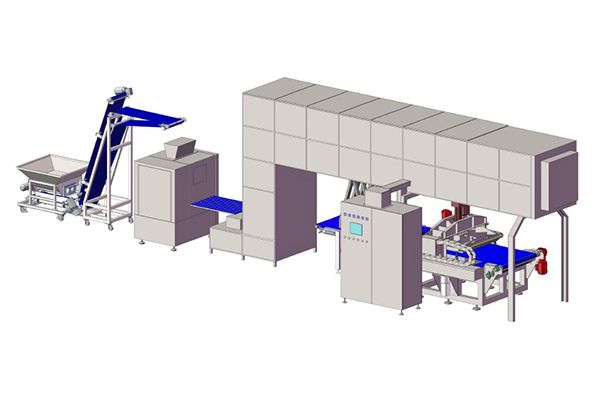

ZLINE is able to provide customers with a complete and full automatic baked croissants production line from dough mixer to package to meet the grand industrial output demand.

Coming to ZLINE with your blank factory layout with necessary parameters, ZLINE will be able and willing to design a line to be placed well at your plant, even can help to design the kinds of function room of a whole factory to help you start up and run your business successfully.

This line is consist of automatic croissants dough forming line, automatic proofing, baking cooling and packing system. Therefore, this kind of line requires much more space of the plant and buget.

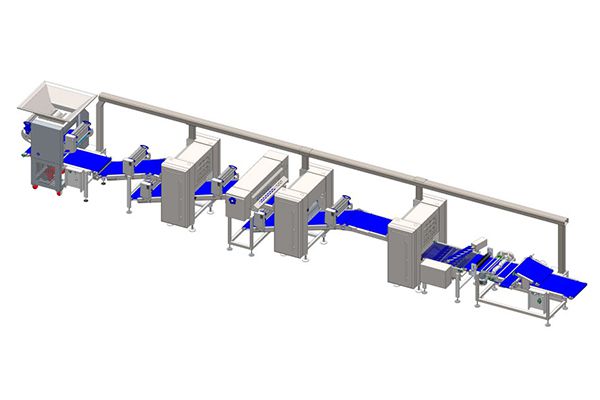

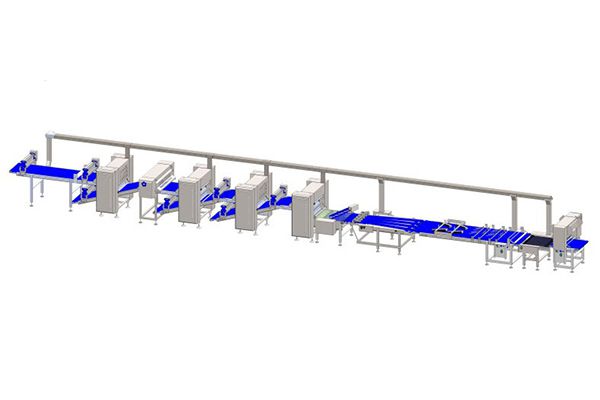

Dough laminating - Croissants forming – Freezing – Proofing – Baking – Cooling - Packing

By increasing the necessary mechanism, several pastries can be produced on the same line like Palmier, chocolate pain, Cinnamon roll, raisins pain and so on to rich your products scope with less investment.