Parameters

| Product size | 8 in (6 in, 10 in, 12 in) |

| Product weight | 28g-130g (adjustable) |

| Industrial output | 8,000–11,000 pcs/hr for 6 in & 8 in 5,400 pcs/hr for 10 in & 12 in |

| Proofing time | 12–20 minutes (adjustable) |

| Baking temperature | 0–400°C (fully controllable) |

| Baking time | 60-90 seconds |

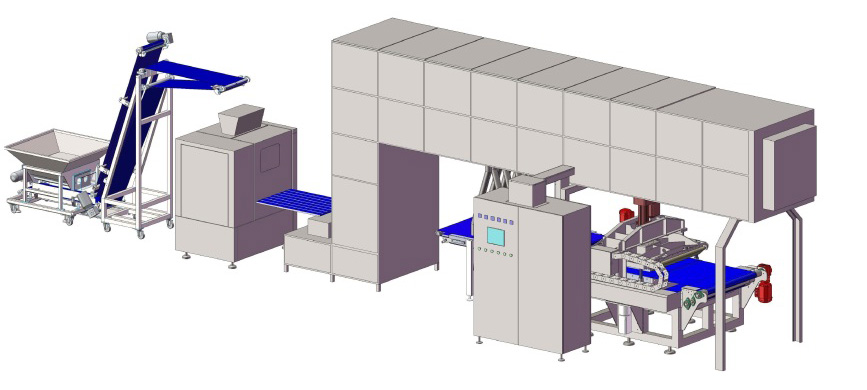

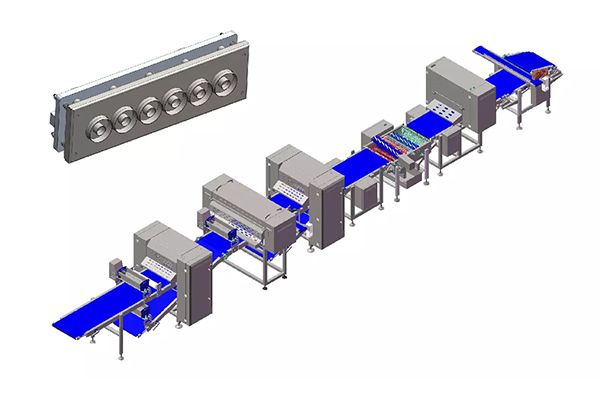

| Baking method | Double-sided baking |

| Cooling time | ≤2 minutes with fan-assisted cooler (customizable) |

| Packaging | 12 tortillas/bag (servo reciprocating packaging machine) |

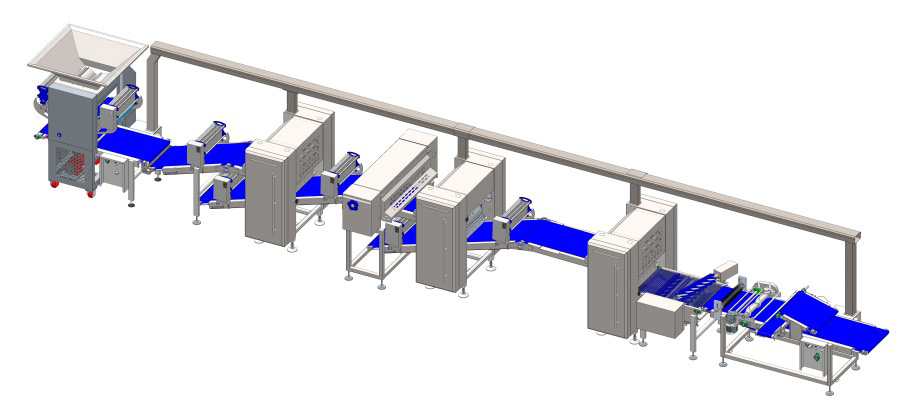

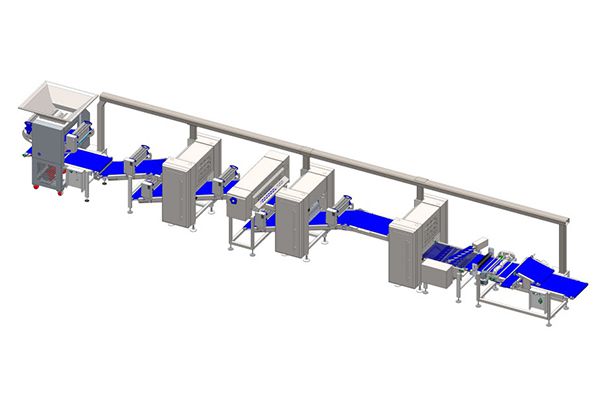

| Mixer | Removable bowl mixer, 200kg/batch |

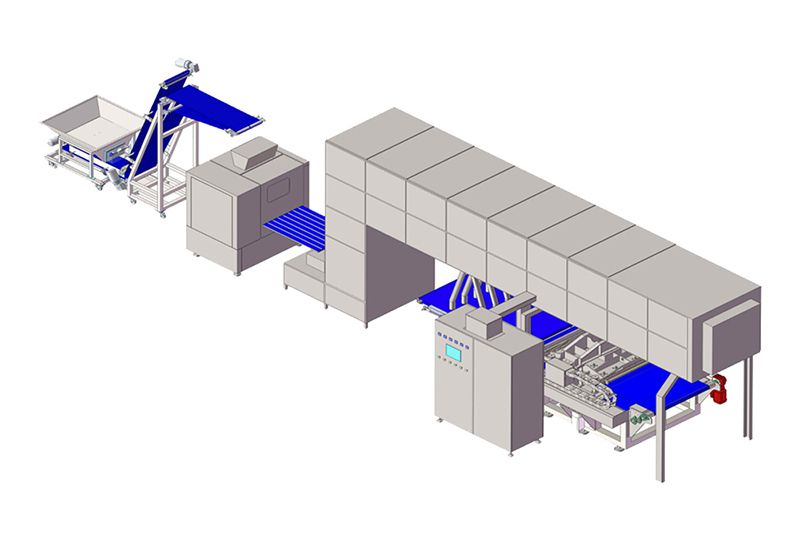

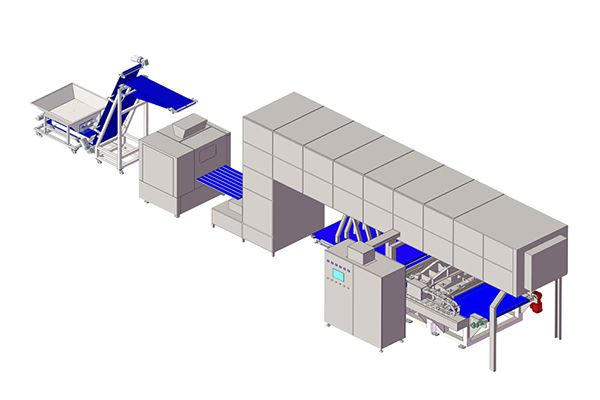

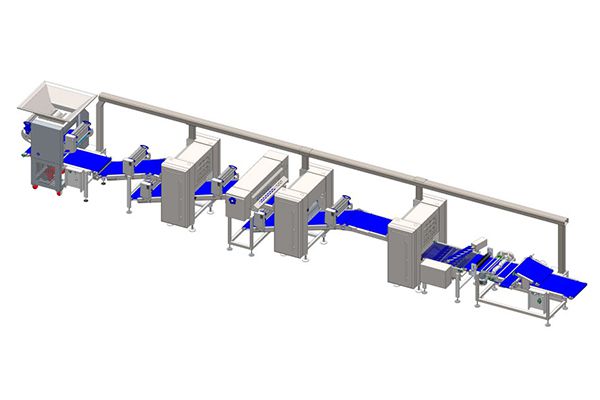

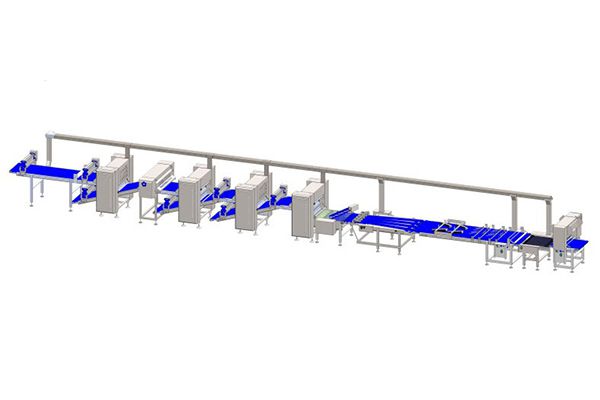

| Line length | 30.85 meters |

| Voltage | 380 V, 50HZ, 3PH |

Features

- Fully customizable for different sizes, thicknesses, proofing times, and production capacities based on customer requirements.

- Equipped with Siemens PLC control system for precise automation, ensuring consistent thickness and texture.

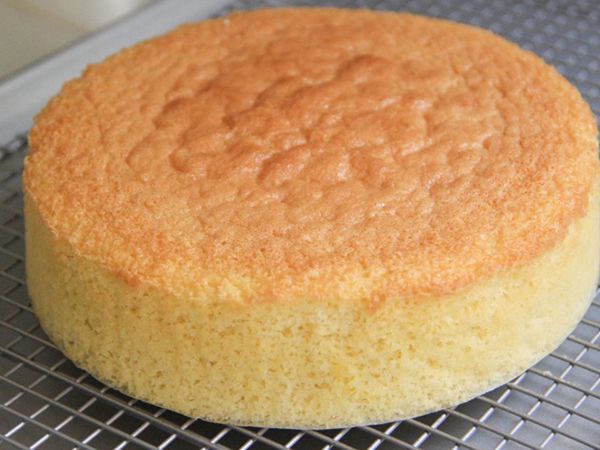

- Features a uniquely designed three-layer steel tunnel oven that supports double-sided baking, providing even heat distribution and a naturally golden finish.

- Baking temperature and duration are easily adjustable to accommodate various bakery product profiles.

- High degree of automation, strong production output, and user-friendly operation and maintenance.

- Final products retain authentic traditional flavor with consistent quality.